Plytanium plywood has more than 50 years of proven performance in construction applications and plytanium sturd i floor panels hold nails firmly and help minimize nail pops that can lead to squeaky floors.

Floor systems t g plywood.

Click to add item roseburg 3 4 x 4 x 8 sturd i floor tongue groove fir plywood subfloor to the compare list.

Cement board works well for tile finish floors because it s strong enough to take a lot of water which may affect the strength of plywood.

Some local codes may require 1 inch thick sheets for joists up to 24 inches apart.

When a roofless partially built structure takes on water the plywood or osb used for floor decking can absorb water swell delaminate and require sanding or replacement before finish flooring.

Plywood can also be made into fencing materials packaging materials scaffolding sheds and shipping containers.

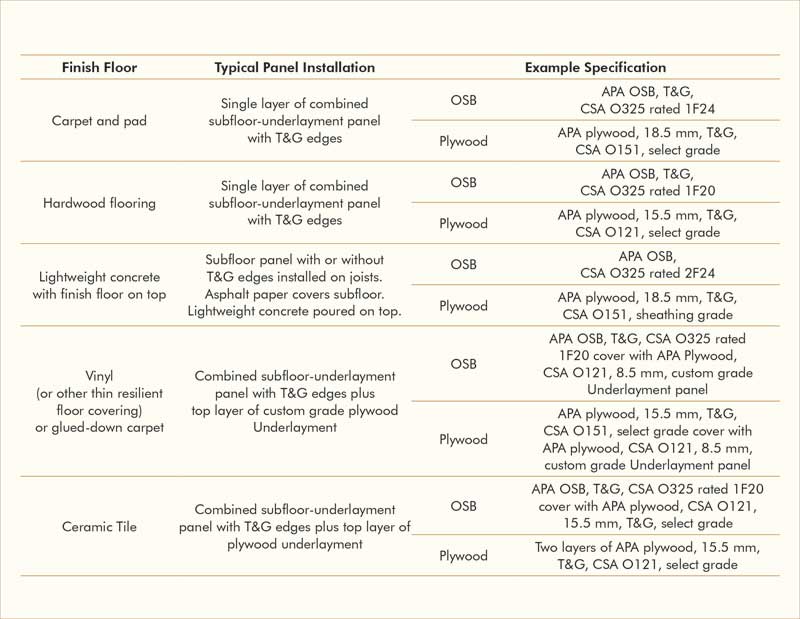

The standard subfloor for joists spaced up to 16 inches apart is 23 32 inch t g sheets.

Fiber cement board is a smoother type of cement board.

Plytanium sturd i floor sub floor panels have helped deliver sturdy stable flooring systems for over five decades.

Alternatives to plywood include cement board osb oriented stranded board and sturd i floor.

Stainable and paintable plywood are often used to make shelving cabinets and furniture.

When used in flooring plywood functions as the subfloor that supports hardwoods tile and carpet floors.

Plywood makes up most of the walls and floors in attics and are sometimes found in laundry rooms closets and other unfinished areas in the home.

The type of osb used for subfloors generally is made with tongue and groove edges t g.